Produkte Beschreibung

With its low melting point, the General-Purpose EVA-g-MAH provides outstanding performance and versatility for applications such as adhesive, surface treatment, and film blowing. This additive is revolutionizing manufacturing processes in a variety of sectors with its low melting point convenience, high-quality film creation, dependable adhesion, varied solvent compatibility, and surface feeding agent capabilities. By using this product in their production processes, manufacturers can increase surface quality, achieve dependable adhesion, optimize film blowing, and customize solvent-based systems. The remarkable attributes and benefits of the General-Purpose EVA-g-MAH product make it a compelling option for purchasers looking to improve surface treatment, solvent compatibility, adhesion, and film quality in their products. With its remarkable qualities and extensive range of applications, the General-Purpose EVA-g-MAH with a low melting point is poised to revolutionize the adhesive, surface treatment, and film blowing industries.

K2G ist ein universell einsetzbares EVA-g-MAH-Produkt mit hervorragenden umfassenden Eigenschaften.

EVA-g-MAH can be used as a film for hot-pressing bonding wood, and the bonding can be completed at a lower hot-pressing temperature. The following is Comparison table of bonding strength of EVA-g-MAH film to poplar board.

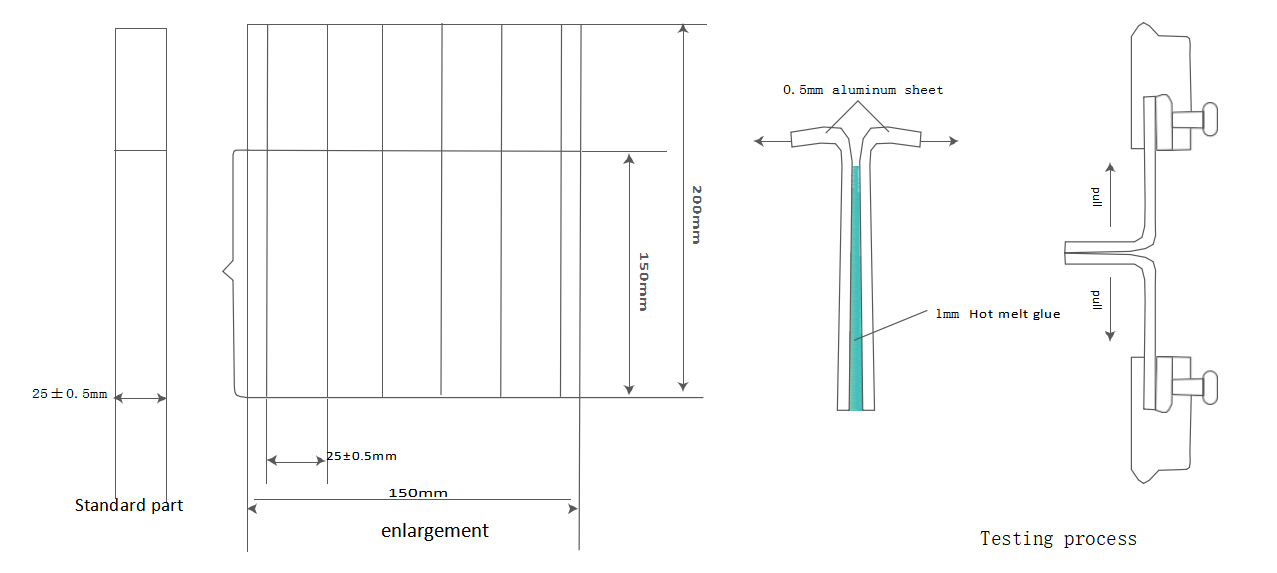

T-type peel strength test (aluminum sheet)

| Modell | T-peel strength N/25mm |

| EVA-VA28 | 160 |

| foreign competitors EVA-g-MAH | 258 |

| K2G | 252 |

Figure 1: T-type test (aluminum sheet) standard parts and test process sketch

It can be seen from the above table that on the bonding metal aluminum, the adhesion of K2G is comparable to that of the American and foreign competitor EVA-g-MAH

Empfohlene Dosis:According to the actual application, taking into account the cost, the amount can be increased or decreased

Verpackung, Lagerung und Transport:20-kg-Kraftsack mit innerem Plastikbeutel. Dieses Produkt ist als nicht gefährlicher Artikel zu behandeln und unter trockenen Bedingungen zu lagern oder zu transportieren; Sonnenlicht und Regen sind zu vermeiden.

Fortschrittliche Ausrüstung!

Ausgestattet mit fortschrittlichen Produktionslinien und einem experimentellen Testzentrum zur Gewährleistung der Produktqualität.

Starke technische Kraft!

Mehr als 10 erfahrene technische F&E-Mitarbeiter sorgen für kontinuierliche Innovation.

Charakteristisch

K2G is a maleic anhydride grafted polymer with ethylene-vinyl acetate copolymer as matrix material, which has strong adhesion to foil, paper and other polar substrates and has a white or yellowish transparent particle appearance.

Vorteil

- Minimal Melting Point Convenience: The product’s low melting point makes processing it simple and boosts production effectiveness. Film manufacturers find it appealing because it streamlines the blowing process while preserving high-quality film.

- High-quality film manufacturing is made possible by the EVA-g-MAH product, which makes films with exceptional mechanical strength, flexibility, and clarity possible. Its remarkable bubble stability and melt strength help to produce films with good physical qualities and a consistent thickness.

- Dependable Adhesion: The product’s superior adhesive qualities guarantee a solid, long-lasting bind between various surfaces. It provides trustworthy adherence in a range of settings, such as textiles, woodworking, packing, and assembly procedures.

- Versatile Solvent Compatibility: The EVA-g-MAH product can be used to formulate solvent-based systems that are customized to meet the needs of certain applications because of its compatibility with a broad variety of solvents. It satisfies a variety of industry needs by providing flexibility in adhesive, coating, and dissolving glue applications.

- Better Surface Quality: The product improves the flow and dispersion of pigments, fillers, and additives by acting as a surface feeding agent. By guaranteeing a smooth and consistent surface finish, it enhances the end product’s surface quality and appearance.

Unser Vorteil

Globale Lieferkette!

Solide Lagerung und Logistik Supply Chain System

Technische Unterstützung

Schutz nach dem Verkauf

Fokus - Leistung - Exzellenz!

Maßgeschneiderte Produkte

Fokus auf F&E

Globale Dienstleistungen

Coace-Zertifizierung!

ISO9001:2015 Zertifizierung

ISO14001:2015 Zertifizierung

EU REACH-Registrierung

Korea K-REACH Vorregistrierung

Vorteil für Unternehmen!

Layout im In- und Ausland, wunderbar zum Mischen

Gestaltung der Inlandsvermarktung

Layout für die Vermarktung in Übersee

Anmeldung

It can be used as Hot melt adhesive for aluminum foil and polyester composite sheet and EVA alloy compatibilizer

It can be used as Hot melt adhesive for aluminum foil and polyester composite sheet and EVA alloy compatibilizer

Film Blowing: To create premium films for industrial, packaging, agricultural, and construction uses, the product is widely employed in film blowing applications. Its exceptional film qualities and low melting point enable the creation of films with exceptional performance.

Hot Melt Adhesive: The material is used in formulations of hot melt adhesive for uses in textiles, woodworking, packaging, and assembly procedures. Strong and long-lasting bonding in a variety of sectors is ensured by its consistent adhesion qualities.

Solvent-Based Systems: The product is used in the production of coatings, dissolving glues, and adhesives based on solvents. Because of its broad range of solvent compatibility, formulations can be tailored to fit the needs of certain applications.

Surface Treatment: The product improves the flow and dispersion of pigments, fillers, and additives by acting as a surface feeding agent. It is used to improve the end goods’ surface quality and appearance in industries including plastics, paints, and coatings.