Maleic anhydride grafts, which differ from physical blending and toughening in that they include both polar aldehyde groups and olefin non-polar lengths, may be strengthened and made tougher by chemically linking with fillers and polymers. There are several potential applications for the ideal mix.

Übersicht

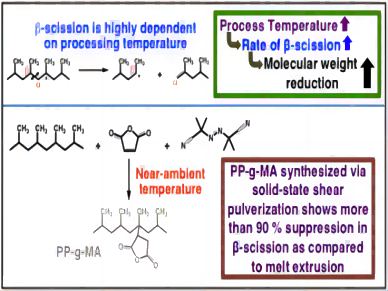

A polymer called maleic anhydride graft is created by grafting maleic anhydride with other substances at the right temperature. The solution approach, melting method, radiation method, and solid phase method are the primary grafting techniques. The melting process is both the most popular and the most significant of them.

Maleic anhydride grafts may be utilized extensively in the modification of materials such PA, PP and PE, wire and cable masterbatch, wood, and other non-polar chain segments of olefins. It primarily serves the purpose of coupling compatibility in the plastics, rubber-coated TPE, and hot-melt adhesive sectors.

The basis for action

A generalized dehydration reaction between the anhydride group and the polar group (-NH2, -OH) can occur in the maleic anhydride graft under the influence of high temperature and screw shear, resulting in a chemical bond and the incompatibility of polar and non-polar substances.

PA that has been hardened by maleic anhydride is one example. Olefins offer good processing and low temperature toughness, whereas PA has high mechanical qualities but weak toughness at low temperatures. It is challenging for PA and olefin to coexist, as PA is a polar polymer while olefin is a non-polar polymer. Currently, the two can be effectively combined if the maleic anhydride graft is utilized (the reaction mechanism is depicted in Figure 1). In other uses, maleic anhydride grafts function similarly.

High Quality Maleic Anhydride Graft Judgment

The following crucial elements must be taken into account when evaluating high-quality maleic anhydride grafts: odor, grafting rate, yellowing index, and if ungrafted maleic anhydride is separated in the later stages of the reaction.It should be emphasized that because so much additional maleic anhydride is not grafted to the main chain, the grafting rate in the grafting reaction is often low. In the reaction system, polymaleic anhydride makes up the majority of the ungrafted maleic anhydride. The end result will thus be a combination combining grafts and polymaleic anhydride if the product of the grafting process is not separated. That is to say, there was a significant difference in the maleic anhydride grafting ratio measured before and after separation. Maleic anhydride grafts of excellent quality often have characteristics such as a low yellowing index, a high grafting yield, and a low strong odor.For instance, the Coace maleic anhydride graft .High grafting rate, low yellowing index, low odor, and good batch stability are all properties of the product. It may be used to modify materials in a variety of sectors, including wire and cable masterbatch, wood-plastic, and PA, PP, and PE. melt TPE, adhesive, and co-extrusion of multi-layer films, among other things.

Of them,W1A grade and W1B grade are made of ethylene copolymer (-MAH), which has high weather resistance, oxygen resistance, and thermal stability. It can also minimize humidity sensitivity, increase dimensional stability, and strengthen composite materials made with glass fibers. influence performance. While the latter ethylene copolymer has high flow and amorphous properties, which can improve polyamide impact properties at -40°C, the former ethylene copolymer has medium viscosity, semi-crystalline characteristics, excellent toughness at room temperature and low temperature.

A PP grafted homopolymer with outstanding impact resistance, extremely high fluidity, and ease of formability, B2 grade has a high grafting rate that may effectively improve PP Coupling with glass fibers, particularly those treated with aminosilane.

strong-density polyethylene graft in the W1H grade comprises HDPE-MAH as its primary constituent, which offers great impact resistance, strong adhesion, and minimal moisture absorption. these products frequently exhibit varied levels of energy efficiency in various applications, thus they should be examined in accordance with the actual use.

Epilogue

Maleic anhydride grafts can be combined in tiny quantities with polymers and fillers during the process of altering materials like PA, PP, and PE, as opposed to physical blending and toughening methods like POE. The finest balance of strength and toughness is achieved by their chemical connection. By including maleic anhydride grafts, polar fillers and polymers can be coupled in the wood-plastic and flame-resistant wire and cable masterbatch industries. Maleic anhydride grafts may also be widely employed in the domains of encapsulating TPE, hot melt adhesives, and multi-layer film co-extrusion because of their outstanding adsorption and adherence to polar substances.