Adding lignin to polymers can improve the mechanical and physical properties. Compared with inorganic fillers, it has the advantages of low density, low cost and renewable, so it is widely used in polymer fillers.

However, because lignin has a large number of polar groups, it has poor compatibility with PP, and it is difficult to achieve the expected effect.

In this article, PP/PP-MA/ Lignin or PP/PB/Lignin.

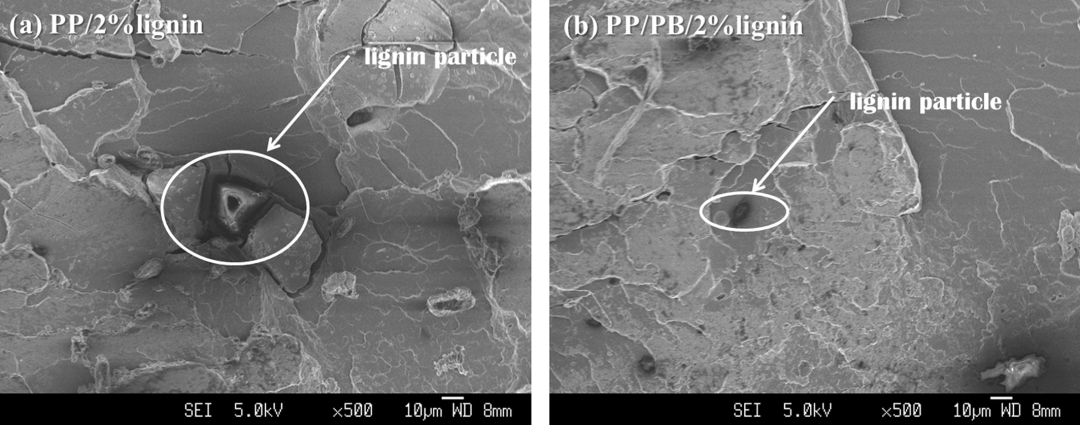

From the fracture morphology in Figure 1, it can be seen that after adding a compatibilizer, the distribution of lignin in PP is more uniform than that without adding a compatibilizer, and the particle size of lignin is smaller, which will benefit the lignin. Factors improve the performance of PP.

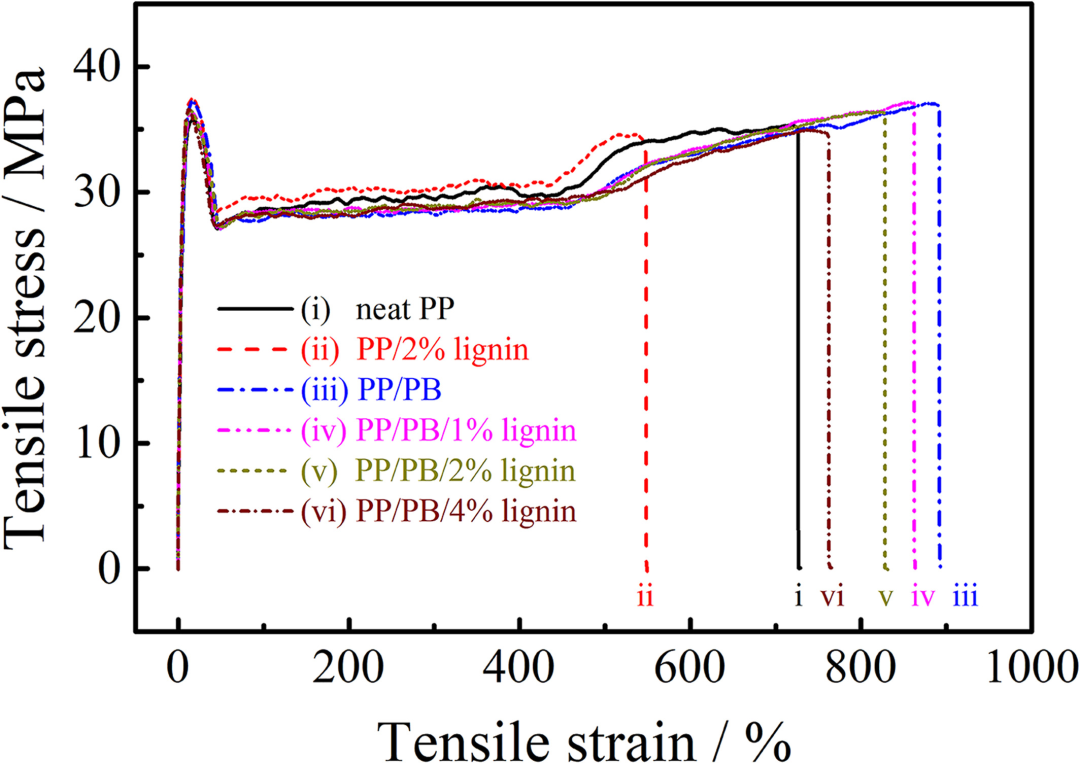

Figure 2 is a graph of the tensile strength of the sample before and after adding a compatibilizer.

The figure shows that compared with pure PP, after adding 2% lignin, its Young’s modulus and yield stress have a certain increase, but its tensile elongation at break has decreased significantly.

After adding 10% compatibilizer, compared with pure PP, its Young’s modulus, yield stress and tensile fracture productivity are all improved, indicating that adding compatibilizer will be beneficial to the dispersion of lignin in PP , so as to further improve its mechanical properties.

In addition, the addition of lignin will also improve the anti-aging performance of the material.

Abb.1 Zugbruchmorphologie der Proben (a) PP/2%-Lignin; (b) PP/PB/2%-Lignin

Abb.2 Spannungs-Dehnungs-Kurven der Proben (i) reines PP; (ii) PP/2% Lignin; (iii) PP/PB; (iv) PP/PB/1% Lignin (ⅴ); PP/PB/2 % Lignin; (ⅵ) PP/PB/4% Lignin