A game-changer in the constantly changing world of materials and polymers is POE-g-MAH (Polyolefin Elastomer-grafted-Maleic Anhydride). This adaptable polymer additive, which boasts multi-functionality, durability, and compatibility with many materials, has a wide range of applications. It also has ecologically beneficial qualities, making it a sought-after option for enterprises looking to improve the performance of their goods. We explore the several uses of POE-g-MAH in this article, stressing both its exceptional qualities and its crucial function as a polymer modifier.

Scope of Application: POE-g-MAH has a wide range of uses in a number of different sectors, including the automotive, electrical and electronics, consumer products, and more. It is a popular option in the production of durable consumer goods, electrical connections, and automotive components because to its capacity to improve nylon’s impact resistance and processability. The wide range of applications demonstrates how adaptable and versatile this polymer additive is.

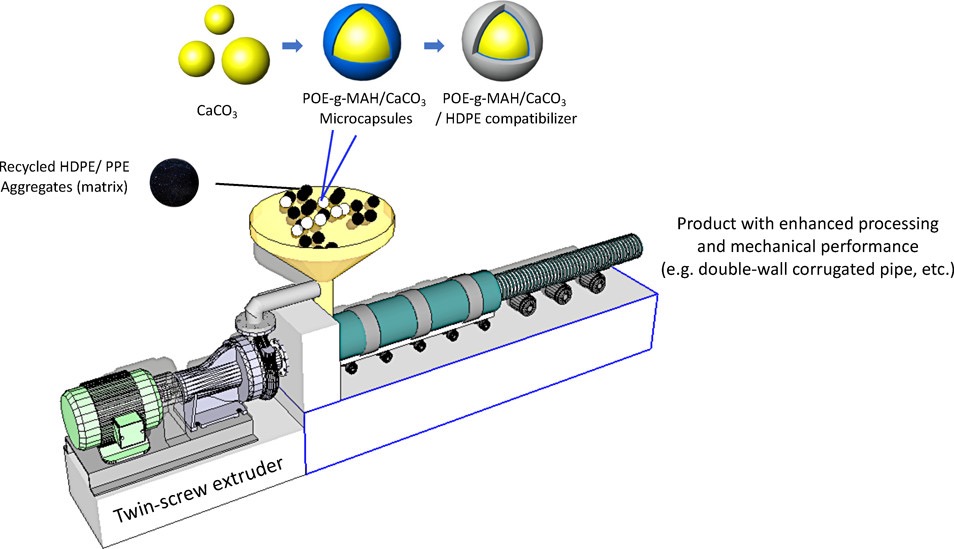

Durability and several uses: The versatility of POE-g-MAH is one of its most notable qualities. The mechanical qualities of a product can be considerably enhanced by adding this addition to polymer matrices. The impact resistance of POE-g-MAH is improved, making it indispensable in applications where toughness and durability are crucial. By serving as a coupling agent, the polymer modifier enhances nylon’s compatibility with polypropylene/polyethylene alloys. The potential for creating new materials and improving performance is increased by this compatibility improvement.

Eco-friendliness: Sustainability has emerged as a crucial factor in contemporary production. This issue is addressed by POE-g-MAH’s ecologically friendly features. Both PA6 (Polyamide 6) and PA66 (Polyamide 66), which are frequently used engineering polymers, are intended to work with it. POE-g-MAH extends product life and lowers the need for frequent replacements by dramatically increasing cold resistance and lowering water absorption, both of which contribute to a more sustainable manufacturing strategy.

Polymer Modifier and Compatibilizer: POE-g-MAH functions as an outstanding polymer modifier, providing a variety of advantages when applied to nylon composites loaded with minerals or straw. The polymer matrix and fillers are more compatible thanks to its coupling agent capabilities, which enhance mechanical strength and overall performance. By improving compatibility, producers may create sophisticated materials with better qualities, creating new opportunities for invention and product development.

With its wide range of applications, versatility, robustness, environmental friendliness, and compatibility with PA6 and PA66, POE-g-MAH has established itself as a crucial polymer addition in several sectors. For producers looking to enhance the performance and sustainability of their goods, its capacity to increase the impact resistance, processability, and cold resistance of nylon, together with its function as a polymer modifier and coupling agent, makes it a useful tool. POE-g-MAH lays the path for innovation and offers up new possibilities for the future of product development as the need for sophisticated materials rises steadily.