The key to establishing the qualities of polymer alloy blending materials is the compatibility of polymer blending components, and it is a crucial foundation for choosing an appropriate blending technique. The qualities of polymer mixing can be enhanced by increasing the systems’ compatibility. The most crucial factor in the formation of this kind of material is the interfacial bonding between components!

1 Making use of interactions like polarity

For instance, PVC resin products frequently require modification and toughening. A popular toughening agent is chlorinated polyethylene (CPE). It is possible to employ polyethylene as a PVC toughening agent because after chlorinating PE, the polarity is enhanced, making CPE/PVC compatible. In the plastics business, similar interactions including hydrogen bonds, acid-base interactions, ion-ion contacts, ion-dipole interactions, etc. are rarely exploited in actual applications.

2 Include a compatibilizer

The most significant and useful technique to increase the compatibility of polymer blends is to include compatibilizers, which will enhance the system’s interfacial qualities.

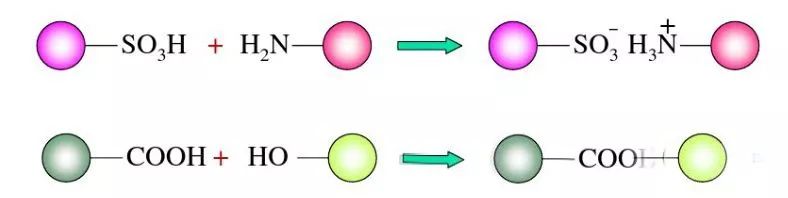

Compatibilizers come in two varieties: non-reactive and reactive. The graft segment or block segment enters the phase area of the matching homopolymer because the additional block or graft copolymer in the polymer blend has the same chemical composition as the homopolymer. The two-phase interface’s interfacial tension is decreased, the phase interface’s bonding performance is improved, and the dispersion of the blend polymer is more uniform thanks to the connecting of the phase domains. Ethylene-propylene copolymers, ethylene-acrylate copolymers, styrene-maleic anhydride copolymers, and similar compounds are examples of these non-reactive block or graft copolymer compatibilizers.

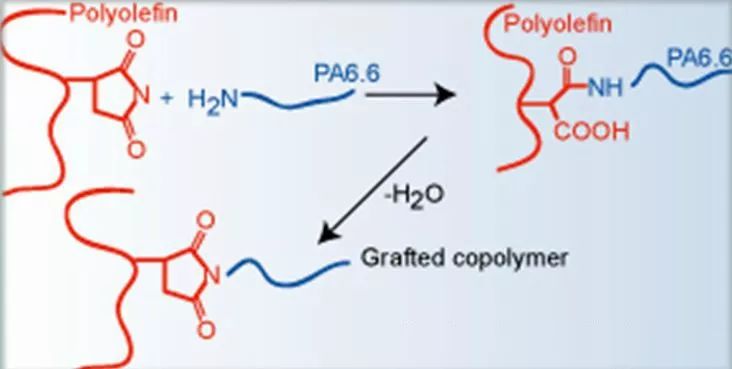

During the mixing process (such as extrusion granulation), the reactive compatibilizer is introduced to the incompatible or weakly compatible polymer blend system and mixes with the functional group on the molecular chain of the blended polymer. The reaction takes place at the phase interface, which enhances the system’s compatibility. Examples of reactive compatibilizers of this kind include ethylene-propylene copolymers, ethylene-acrylate copolymers, PE-g-MAH, PP-g-MAH, POE-g-MAH,EPDM-g-MAH, and others.

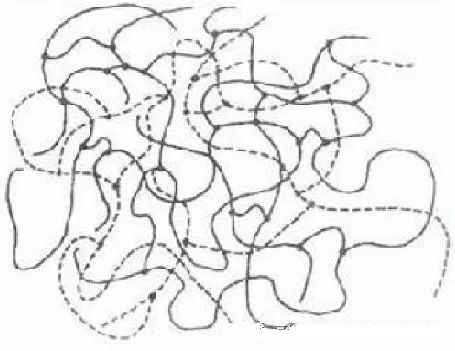

Of course, cross-linking (such as dynamic cross-linking or irradiation cross-linking) or combining the two polymers into a stable mutual polymer using interpenetrating polymer network technology (IPN) can also increase the compatibility between PE/PP. It is connected to a network to increase compatibility.

Model of the Interpenetrating Polymer Network (IPN)

Polymer blends were first created to increase toughness, but they have since been modified to enhance all polymer characteristics and are now used in practically every industry that uses polymer materials. Continued research into effective blending techniques and the creation of novel compatibilizers or compatibilizers remain the primary development trends. Reactive compatibilizer technology is one of the most important ones for modifying polymer mixing among them. It provides a number of benefits, including little addition, low cost, and strong compatibilization. It is a useful method for enhancing the cohesion of phase interfaces and the compatibility of polymer blends, and it has a promising future for use.