Introduction to polyamide-6

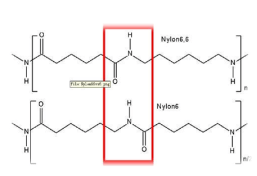

Polyamide (polyamide, PA) is usually called nylon (Nylon), which is a heterochain polymer containing amide groups (-NHCO-) in the main chain. It can be divided into two types: aliphatic and aromatic. It is the earliest developed and widely used Largest thermoplastic engineering material.

The main chain of polyamide contains many repeated amide groups. It is called nylon when it is used as a plastic, and it is called nylon when it is used as a synthetic fiber. According to the number of carbon atoms contained in diamines and dibasic acids or amino acids, a variety of different polyamides can be prepared. At present, there are dozens of polyamide varieties, among which polyamide-6, polyamide-66 and Polyamide-610 is the most widely used.

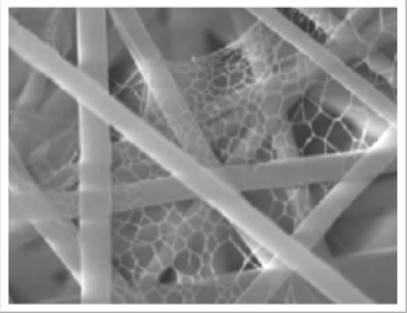

Polyamide-6 is an aliphatic polyamide, which has excellent properties such as light weight, high strength, wear resistance, weak acid and weak alkali resistance, and some organic solvents, and easy molding and processing. It is widely used in the fields of fibers, engineering plastics, and films. The molecular chain segment of PA6 contains a strong polar amide group, which is easy to form hydrogen bonds with water molecules. The product has the disadvantages of high water absorption, poor dimensional stability, low impact strength in dry state and low temperature, and poor resistance to strong acid and strong alkali.

Leistung

Advantages of Nylon 6:

High mechanical strength, good toughness, high tensile and compressive strength. It has strong absorption capacity for impact and stress vibration, and its impact strength is much higher than that of ordinary plastics, and it is better than acetal resin.

The fatigue resistance is outstanding, and the workpiece can still maintain the original mechanical strength after repeated inflection.

High softening point, heat resistance.

The surface is smooth, the friction coefficient is small, and it is wear-resistant. When used as a movable mechanical component, it has self-lubrication and low noise. It can be used without lubricant when the friction is not too high.

Corrosion-resistant, very resistant to alkalis and most salt solutions, also resistant to weak acids, motor oils, gasoline, aromatic compounds and general solvents, inert to aromatic compounds, but not resistant to strong acids and oxidants. It can resist the erosion of gasoline, oil, fat, alcohol, weak alkali, etc. and has good anti-aging ability.

Self-extinguishing, non-toxic, odorless, good weather resistance, inert to biological erosion, good antibacterial and mildew resistance.

It has excellent electrical performance, good electrical insulation, high volume resistance of nylon, high breakdown voltage, and can be used as power frequency insulating material in dry environment, and has good electrical insulation even in high humidity environment .

The parts are light in weight, easy to dye and form, and can flow quickly due to low melt viscosity. It is easy to fill the mold, the freezing point is high after filling the mold, and it can be shaped quickly, so the molding cycle is short and the production efficiency is high.

Disadvantages of nylon 6:

Easy to absorb water, high water absorption, saturated water can reach more than 3%. To a certain extent, it affects dimensional stability and electrical properties, especially the thickening of thin-walled parts has a greater impact, and water absorption will also greatly reduce the mechanical strength of plastics.

The light resistance is poor, and it will oxidize with oxygen in the air in a long-term high-temperature environment. At the beginning, the color turns brown, and the surface is broken and cracked.

The requirements for injection molding technology are strict, and the existence of trace moisture will cause great damage to the molding quality; the dimensional stability of the product is difficult to control due to thermal expansion; the existence of sharp corners in the product will lead to stress concentration and reduce the mechanical strength; if the wall thickness is not Uniformity will lead to distortion and deformation of the workpiece; high equipment precision is required for post-processing of the workpiece.

It will absorb water and alcohol and swell, and it is not resistant to strong acids and oxidants, so it cannot be used as an acid-resistant material.