The coupling agent is an organosilicon compound with a special structure. In its molecule, it has both reactive groups that can combine with inorganic materials (such as glass, cement, metal, etc.) and reactive groups that can combine with organic materials (such as synthetic resins, etc.). Commonly used theories include chemical bond theory, surface infiltration theory, deformation layer theory, constrained layer theory, etc. The coupling agent is used as a surface modifier to improve the dispersion and adhesion of plastics filled with inorganic fillers

The role of coupling agent:

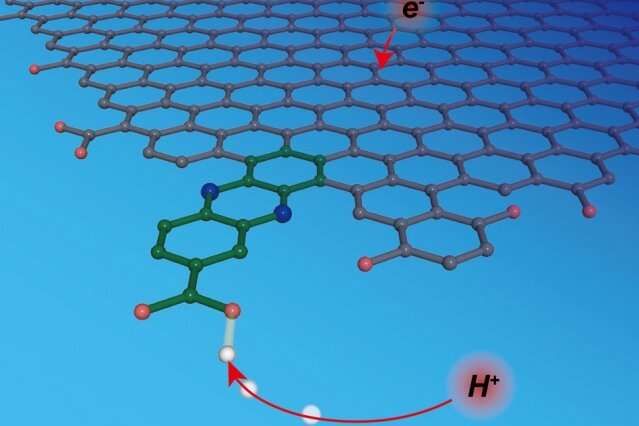

(1) Coupling modification is a chemical coupling reaction on the particle surface, and the particle surface can be well compatible with organic matter after being treated with a coupling agent. Shi Weixian and others used silane coupling agent KH-570 to modify the surface of magnetic Fe3O4, and further analyzed and characterized the magnetic composite particles. Fe3O4 magnetic particles were treated with silane coupling agent KH-550; the surface characteristics of modified particles were detected by scanning electron microscope. The results show that both Fe3O4 and modified Fe3O4 particles are irregular in shape, but the dispersibility of modified Fe3O4 particles is obviously better than that of unmodified Fe3O4 particles. This is because the coupling agent on the surface of the particles prevents the agglomeration of Fe3O4 particles. The particle size test results of Fe3O4 and modified Fe3O4 show that modified Fe3O4 has larger specific surface area and smaller particle size.

The application of silane coupling agent as a surface modifier in metal anti-corrosion pretreatment is its latest application. In order to obtain an anti-corrosion coating that combines well with the metal substrate, it is necessary to select a suitable coating system, formulate a reasonable coating process, and carry out strict surface pretreatment. There are two methods for surface pretreatment: ① Deposit a layer of organic film on the metal surface by plasma polymerization, but the high cost of this method limits its popularization and application; ② Treatment with organic silane coupling agent aqueous solution, in the A very thin film of organosilane is deposited on the metal surface. Since the silane coupling agent can form trihydric silanol after hydrolysis, the alcoholic hydroxyl groups can react with each other to form a cross-linked dense network hydrophobic film, because the surface of this film has organic functional groups that can react with the resin Therefore, the adhesion of the paint film will be greatly improved, and the ability of anti-corrosion, anti-friction and impact resistance will also be improved.

(2) In the research and production of plastics, a large amount of cheap inorganic fillers (or reinforcing agents) are usually used. This can not only increase the quality of plastics and reduce the cost of products, but also improve some properties of plastic products. However, due to the significant differences in chemical structure and physical form between inorganic fillers and organic polymers, the lack of affinity between the two often affects the mechanical properties and molding processability of plastic products. Through the chemical reaction or physical coating of the coupling agent and the inorganic filler, the surface of the filler is changed from hydrophilic to lipophilic, so as to achieve a tight combination with the polymer and improve the strength, adhesion, electrical properties, and hydrophobicity of the material. Significantly improved performance and anti-aging properties.

Some people have used various silane coupling agents to treat the surface of glass fibers, and the results show that: the coupling agent containing amino groups has a better effect on the surface treatment of glass fibers than the coupling agent without amino groups, because the amino group of the coupling agent and the additive And the amino group in the matrix has affinity, together with the auxiliary agent that plays a cross-linking role, the interface of the composite material has better adhesion, and there is no such function without the amino group; the amino group can also be combined with the grafted The acid anhydride functional group reacts to form a chemical bond across the interface, which improves the bonding strength of the interface and improves the overall performance of the composite material.