As a new wood-like material, wood-plastic composite materials have the dual advantages of wood and plastic. The development of wood-plastic composite materials industry can not only improve the utilization rate of agricultural and forestry solid waste, but also realize the sustainable development of wood and help carbon neutral and carbon peak.

What is HPC?

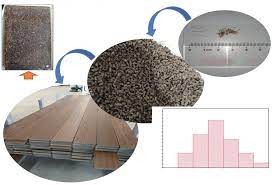

HPC (Harvest Plastic Composite Material) is a kind of fiber-like highly filled composite material obtained by compounding and modifying herbaceous plants such as rice straw, straw, reeds and other thermoplastic resins such as polyethylene, polypropylene and polyvinyl chloride as raw materials through proprietary mixing equipment.

What are the advantages of WoP composites?

The highest content of plant fiber reaches 80%, which has the characteristics of no decay, no insects, good weather resistance and flexible processing; and high mechanical properties, low water absorption, no deformation, no warping and high nail holding force; WoP material can be sawed, nailed, riveted and planed like wood; and extruded, injected and recycled like plastic.

The straw fiber preparation of the “Wo Plastic” composite materials, but also to solve the problem of burning a large number of crop straw, turning waste into treasure.

Application areas of straw-plastic composites

With the advantages of low water absorption, high nail holding force, not easy to deformation, not easy to warp, etc., the composite material can be widely used in construction materials, landscaping, home decoration, furniture panels, flooring substrates, logistics packaging, transportation facilities and other fields. Specifically, outdoor gardens include park benches, pavilions, connecting bridges, fences, etc.; construction fields such as doors and windows products, flooring, decorative wall panels, etc.; packaging and logistics industry pallets, etc.; automotive parts such as flame retardant reinforced modified plastic replacement; transportation fields such as signage, etc.

Market space of WoP composite materials

On the one hand, wood can be gradually replaced by wood composite materials to achieve wood sustainability. In 2020, China’s wood consumption will be around 800 million cubic meters, of which nearly 70% of wood depends on imports. On the other hand, gram-plastic composite materials can improve the utilization rate of agricultural solid waste and solve the problem of straw burning, China is a large agricultural country, with the rise in annual grain production, straw production has also been increasing, and at this stage has reached 1 billion tons / year.

It is estimated that China will consume 1 billion tons of wood in 2021, and if the replacement rate of 20% is calculated, the future market of straw-plastic materials will exceed 200 million tons, and the output value can reach more than 1.5 trillion RMB.

From the perspective of industry prospect, the filler used in Harvest Plastic materials will not be woody plants, but mainly herbaceous plants, which can solve the problem of wood shortage and realize the sustainable development of wood; the “Harvest Plastic” composite material prepared by straw fiber also solves the problem of burning a lot of crop straw, turning waste into treasure and compounding the national policy guidance. Overall, with the expansion of the industry scale and market awareness of the WoP composite materials, WoP composite materials market specific very broad space.