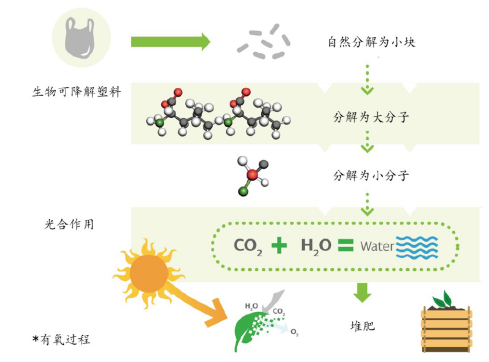

From the perspective of the ecological benefits of biodegradable materials, biodegradable materials can not only greatly reduce the impact of waste plastics on the environment, but also be an effective carrier to realize resource recycling and utilization;

●The future material star – biodegradable materials

1. The huge application market of biodegradable plastics guides the rapid development of the industry

The field of biodegradable materials is in the ascendant and has a broad market space. Biodegradable plastics are the most obvious and largest application scenario of biodegradable materials at this stage. They are mainly used to replace traditional non-degradable plastics, so as to solve the “white pollution” problem caused by traditional plastics. It can be said that biodegradable materials can not only greatly reduce the impact of waste plastics on the environment, but also be an effective carrier to realize resource recycling and utilization.

2. Biodegradable materials are widely used and the potential market is huge

The application fields of biodegradable materials are very extensive, and they can also achieve better applications in many fields such as biomedicine, health care, textile fibers, automobile manufacturing, agricultural production, 3D printing, and architectural coatings, demonstrating huge market potential and development In terms of prospects, it can be said that biodegradable materials are the “industrial monosodium glutamate” in the new era.

From the perspective of application fields, biodegradable materials are currently used in many fields, including flexible packaging, rigid packaging, consumer goods, textiles, agriculture, horticulture, construction, coatings, electronics and other fields, among which the largest application volume is still In the packaging industry, biodegradable materials account for 47% of the market.

●Diversified development of biodegradable materials

At present, biodegradable materials can be divided into bio-based and petroleum-based according to the source of raw materials. The basic raw materials of bio-based plastics are renewable natural biomass resources such as starch (such as corn, potatoes, etc.), plant straw, chitin, etc. Bio-based degradable plastics include polylactic acid (PLA), polyhydroxyalkanoate polymers (PHAs), whole starch based, cellulose, etc.

Petroleum-based plastics are formed with petroleum and petrochemical products as monomers. Petroleum-based degradable plastics include dibasic acid diol copolyester series (polybutylene succinate (PBS), polyadipate/para Butylene phthalate (PBAT)), carbon dioxide copolymer (PPC), polycaprolactone (PCL), polyglycolic acid (PGA), etc.

Since different materials have different properties, different materials can also correspond to different application fields. At present, PBAT, PBS, PLA, etc. are mainly produced on an industrial scale in the Chinese market and occupy a large market share. PPC, PCL, PGA, PHA, etc. are used as functional materials.

Among them, PLA and PBAT/PBS have the highest degree of industrialization, covering a relatively wide range of application fields, and downstream applications can effectively support raw materials. Key domestic and foreign enterprises have achieved layout in these fields.

However, the emerging biodegradable materials represented by PPC, PCL, PGA, PHA, etc. have not yet formed a large global market due to various reasons such as the difficulty in supporting the industrial application scale, the difficulty in solving the key problems of industrialization, and the high cost of industrialization. production capacity.