An overview of toughening modification

A material’s toughness relates to its capacity to absorb energy during plastic deformation and fracture. The amount of strain energy a material can withstand before it breaks may be used to determine how tough it is. Impact strength, a metric to assess the toughness and fracture resistance of materials under high-speed impact, may often be used to indicate the toughness of materials.

Elastomer Toughening Mechanism

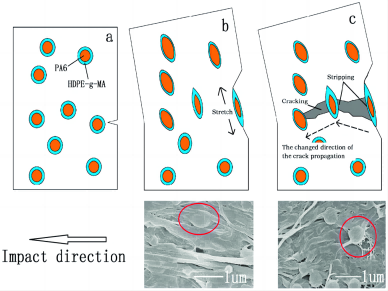

In the past, rubber particles were used to toughen up elastomers, but more recent developments have allowed for the addition of a variety of new elastomers. Elastomer particles primarily play the roles of inducing many crazes and shear bands in the plastic matrix and of regulating the propagation of crazes. The plastic matrix produces numerous crazes and shear bands, which directly absorb the impact energy and can also terminate the crazes and stop them from becoming cracks, provided that the interface between the elastic particles and the plastic has a good bonding effect.

Rubber (elastic) particles mostly cause shear bands in substrates with a certain degree of toughness, whereas elastic particles primarily cause crazing in plastic substrates with brittle substrates. Three ideas have been put out in this regard: the shear yield theory, the multiple craze hypothesis, and the microcrack theory. The orientation of the polymer is near to the stretching direction owing to shear deformation during the actual stretching process of elastomer-toughened plastic samples, which is more favorable for the creation of crazes. These interactions encourage the material to toughen more effectively.

Commonly used elastomer toughened materials

High-impact resins, such as CPE, MBS, ACR, SBS, ABS, EVA, modified petroleum resin (MPR), etc.; high-impact rubber, such as ethylene-propylene rubber (EPR), ethylene-propylene-diene rubber (EPDM), butadiene Nitrile rubber (NBR), styrene-butadiene rubber, natural rubber, butadiene rubber, neoprene rubber, polyisobutylene and butadiene rubber, etc.

Superior modification:

A “composite material” is created by mixing a second component with the polymeric matrix, and “reinforcement” refers to the process of compounding that greatly boosts the material’s mechanical strength. Reinforcing agents or active fillers are substances that can improve the polymer matrix’s mechanical strength. In addition to liquid crystal and nanomaterial reinforcement, the most common method of plastic reinforcement involves adding reinforcing fibers and fillers.

1. Modification of filler reinforcement

The molecular chains of the polymer are strongly attracted to the active surface of the powdery filler particles, forming physical crosslinks between the chains. The particles with adsorbed molecular chains can distribute the load uniformly, lessen the likelihood of material failure, and so serve as reinforcement. The stronger the binding force and more pronounced the strengthening effect, the better the affinity of the particles and molecule chains at the contact. Powdery fillers like wood flour, carbon black, light silica, magnesium carbonate, zinc oxide, and others are frequently employed, and their performance may be greatly enhanced by compounding them with rubber or plastic.

2. Fiber bolstering

Rubber and plastics both use fiber reinforcing, but significantly differently. Fiber fillers primarily act as skeletons to support the weight in rubber goods. Typically, a fiber mesh fabric is employed. The purpose of fiber-filled plastic reinforcement is to rely on its composite effect, which uses the fiber’s high strength to bear stress and the matrix resin’s plastic flow and bonding with the fiber to transmit stress. Various natural fibers, such as cotton, hemp, silk, and wool, as well as their textiles, as well as glass fibers and specialized fiber fillers, such as carbon, graphite, boron, ultrafine metal, and single crystal fibers (whiskers), are examples of materials used to fill fibers.

3. Liquid crystal augmentation

The major reason liquid crystals are improved is because thermotropic main chain liquid crystals, which are often used in the preparation of high-performance composite materials, may produce microfibers in the blends to serve as reinforcing agents.

Numerous techniques, including as the inclusion of fillers, liquid crystal modification, etc., have the effect of strengthening while toughening as a result of the introduction of the aforementioned reinforcement and toughening procedures. The goal of polymer modification is to produce materials with superior overall qualities, however when it comes to application, the right technique should be chosen based on the performance requirements.