The engineering material polyamide (also known as nylon) is widely used in everything from mechanical equipment to everyday items. The qualities of nylon are required to meet a variety of application situations. Although nylon is a highly durable material, it has the drawback of being prone to water absorption. In most cases, reinforcing modification is necessary to guarantee that nylon meets the criteria of the numerous applications. The most popular of these is glass fiber reinforced nylon.

6 fundamental understandings of glass fiber reinforced nylon

1. How are the characteristics of glass fiber reinforced nylon typically improved?

Its mechanical strength, stiffness, heat resistance, creep resistance, fatigue strength, and reduction in elongation, molding shrinkage, and hygroscopicity as compared to pure nylon are all noticeably better.

2. How to categorize and define glass fiber

Glass fiber is a superior performing inorganic non-metallic material. The primary raw material is silicon dioxide, to which particular metal oxide minerals are added and heated until they melt. Molten glass then emerges through the nozzle. Stretching and quick cooling cause the material to form into very thin continuous fibers with a diameter of a few microns to more than twenty microns.Glass fiber has a higher tensile strength than other natural and synthetic fibers, but it is more brittle and has a low elongation at break.

According to length, glass fiber is separated into short and long glass fiber. Short glass fiber is often less than 6mm in diameter, or perhaps only 0.2-0.6mm, whereas long glass fiber may typically reach 6 to 25mm in manufacture.

3. What distinguishes long glass fiber reinforcement from short glass fiber reinforcement?

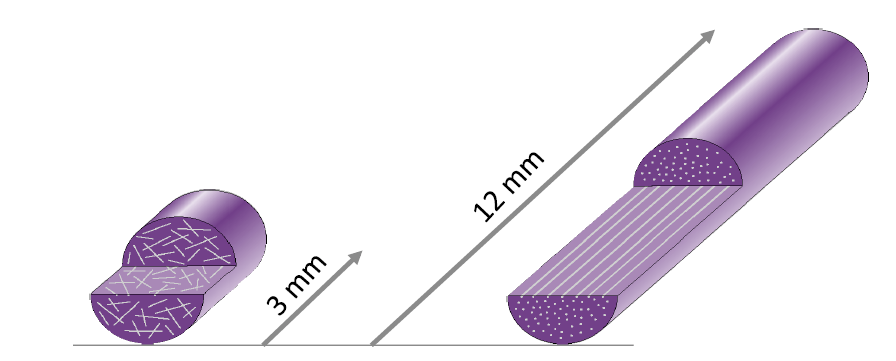

Because of differences in size and internal glass fiber distribution, long and short glass fiber reinforced nylon particles have varied qualities.

Short glass fiber reinforced nylon with internal disordered anisotropy is shown on the left, whereas long glass fiber reinforced nylon with internal isotropy is shown on the right.

long nylon reinforced with glass fiber: It has less anisotropic shrinkage than short glass fiber, which lessens the impact of warpage. Additionally, it outperforms short glass fiber reinforced nylon in terms of stiffness, abrasion resistance, age resistance, and heat resistance.

In comparison to long glass fiber nylon, short glass fiber nylon has increased processability, stiffness, and strength. It is also less prone to floating fibers during injection molding.

4. Utilization of nylon reinforced with glass fiber

Car parts include: the cooling water chamber, the intake manifold, the mirror frame bracket, the ventilation grille, the door handle, the throttle body, the fan cover, the shift control lever cover, the hand brake, the accelerator pedal, the gear, etc.

car intake manifold

car handbrake

Mechanical parts: water pumps, water valves, bearings, bushings, gears, brackets, rollers, etc.

Sports equipment: ski equipment, baby carriages, bicycles, fitness equipment parts, etc.

Office equipment: seat brackets, pulleys, shafts, shredder gears, printer parts, etc.

5. How is the situation with "floating fiber" made of glass fiber reinforced nylon?

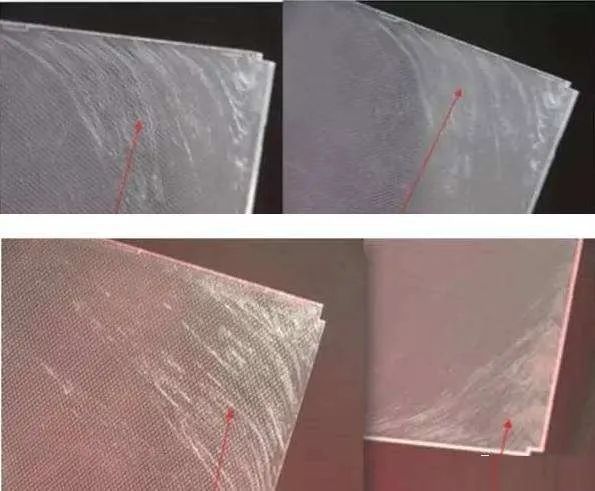

Glass fiber really forms floating fiber, which is exposed glass fiber that forms white, rough radial traces after condensation, lowering the surface quality of the final product.

Then why does the "floating fiber" exist? Due to their distinct densities and mutual incompatibility, plastic and fiberglass frequently separate.

The plastic melt progressively builds up on the surface as a result of friction caused by the screw, nozzle, runner, and gate throughout the flow process. Nylon is a crystalline material, but glass fiber can encourage crystallization. Fast cooling results from quick crystallization, and quick cooling makes it more difficult to bind and cover the glass fiber with resin, which makes glass fiber exposure more likely.

6.How to fix the floating fiber issue in reinforced nylon injection molding

a. Increase nylon and glass fiber compatibility. To improve the material's compatibility with nylon resin, the uniformity of the dispersed phase, the interface bonding strength, the reduction of glass fiber and resin separation, and the exposure of glass fiber fibers, add compatibilizer, dispersant, and lubricant.

b. Increase the injection rate and mold temperature. The most important impact is that of raising the mold temperature, which may greatly improve and lower the resistance of the melt flow to avoid the buildup of glass fibers. The relative speed difference between glass fiber and resin may be decreased by increasing injection speed, further lowering the buildup of glass fiber.

c. Slow the screw down. Especially when the glass fiber is long, it will cause uneven length due to the breakage of some glass fibers, causing the strength of the plastic parts to vary and the mechanical properties of the product to be unstable. As a result, the screw speed should not be too high when the glass fiber reinforced plastic is plasticized in order to avoid excessive friction and shear force and aggravate the "floating fiber" phenomenon.

Injection with high material temperature, high mold temperature, high pressure, high speed, and low screw speed is advantageous to enhance the "floating fiber" phenomena, generally speaking.